With the world in an ever-increasing rush to adopt eco-friendly electric mobility, competition among carmakers to gain a market edge has intensified. Hyundai Transys, the powertrain manufacturing arm of the Hyundai Motor Group, is making some notable progress in this area.

In response to the explosive global demand for hybrid cars, Hyundai Transys has developed a next-generation hybrid drive system with the best efficiency and performance possible, and is increasing the production capacities of key production bases. In June this year, it secured momentum by signing a contract to supply EV drive systems to the Saudi EV manufacturer, Ceer. The EV drive system, which integrates a motor, inverter, and reducer as a single structure, is a product independently produced by Hyundai Transys.

Over the years, Hyundai Transys has prepared for intensifying competition in the global green car market by building up its line of electrified drive systems, which is now broad enough to enable a flexible response to diversifying market needs in EVs and hybrids. In the development of new electrification technologies, Hyundai Transys remains focused on performance improvements in line with heightening consumer expectations of green cars, to attain and maintain leadership in the electrified mobility market.

The Hyundai Transys Hwaseong Drivetrain R&D Center

Opened in 2007, the Hwaseong Drivetrain R&D Center has been at the hub of Hyundai Transys’ development, creating internal combustion engine components such as transmissions and axles, and more recently EV drive systems and reducers, not to mention hybrid drive systems. Staffed by some 600 powertrain research personnel, the Hwaseong Drivetrain R&D Center is a 49,587 m² site with one research building, four test buildings, and numerous utility facilities.

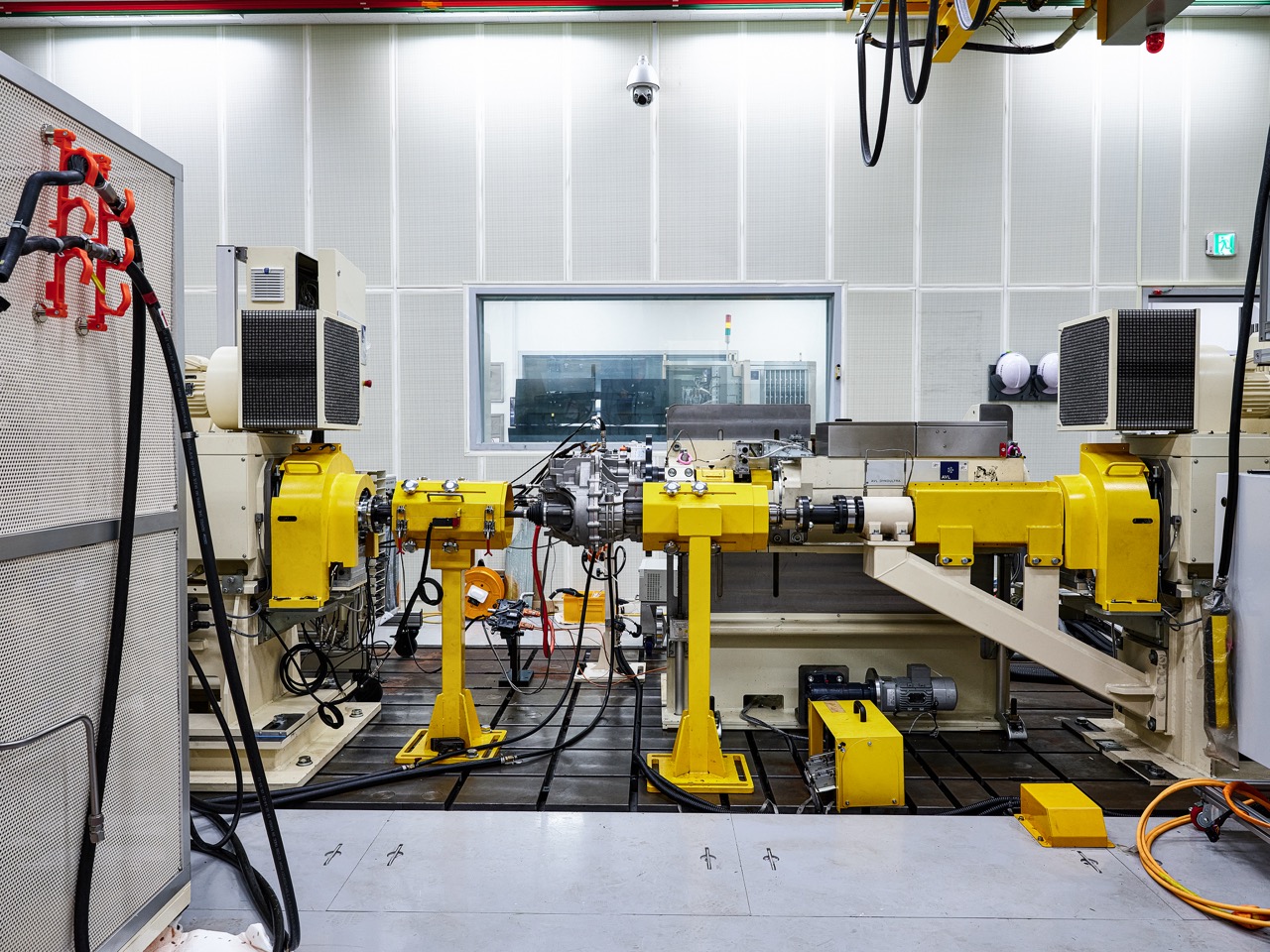

Test Building 4 is the latest addition to the facilities at the Hwaseong Drivetrain R&D Center. Boasting numerous electrified powertrain testing technologies, Test Building 4 is dedicated to electrification tests, and is a major part of the strategy to take the Hyundai Motor Group’s electrified mobility business to new heights. Researchers and engineers at the center’s Electrification Testing and Development Lab in particular have been living and breathing technological innovation.

Breakthrough in Electrified Powertrains Achieved Through the Relentless Pursuit of Excellence

In the Efficiency Test Cell of the Electrification Testing and Development Lab, measurements are performed to discern how efficiently the power generated by hybrid engines is transferred to drive shafts. These measurements are one of the tests performed to validate the performance and efficiency of hybrid transmissions, and relate directly to the energy efficiency of cars.

Transmission performance data is checked in real time using monitors. Torque changes identified in performance data allow for a detailed analysis of a transmission’s power transfer efficiency. Collected data are used to facilitate collaboration with design teams, where improvements and evaluations are made.

Hybrid drive systems as well as EV drive systems are tested at the Electrification Testing and Development Lab. EV drive systems go through tests of their electric power efficiency and a battery of other performance traits. EVs use a reducer instead of a transmission to reduce and convert the motor’s high RPMs to drive power. Needless to say, evaluation criteria that are different from those applied to the testing of ICE transmissions are applied to the testing of EV reducers, and the configurations of the testing equipment used also differ. Since EV and hybrid drive systems use high-voltage power, there are a multitude of safety and measurement considerations. Accordingly, Hyundai Transys is continuously acquiring new technologies as needed, such as battery simulators and precision electric power analyzers.

Hyundai Transys’ latest R&D achievement is an independently developed next-generation hybrid drive system. Featuring a double motor (P1 + P2) configuration for a 10%+ improvement in output, the new hybrid drive system boasts proprietary technology, right down to the basic performance and power transfer efficiency of the transmission and motor unit.

the fruit of focused innovation, highlighting the strengths of Hyundai Transys

in the global transition to electrified mobility.

- Senior Engineer Lee Jae-doo

of the Electrification Performance Test Team -

The Electrification Performance Test Team had set out to develop the new hybrid drive system with the critical demands of global electric mobility consumers in mind and the bar raised commensurately high. As a result, a next-generation hybrid drive system was developed with the best efficiency and performance the world has ever seen. This achievement is the result of the engineers' relentless evaluation and improvement efforts.

The next-generation hybrid drive system is not just an excellent electrification product but has substantial value, as it means that Hyundai Transys now is a company with the capacity to independently develop world-class electrification technologies. This latest development marks a turning point for Hyundai Transys as it grows into a company with proprietary technology.

Proven Durability for Greater Value in Green Cars

The Electrification Reliability Test Team handles the durability testing of all powertrains developed and produced by Hyundai Transys. It is at the Virtual Vehicle Test Room where hybrid engines and transmissions are tested for their durability.

New cars come with warranties that are valid for a certain period of time and distance driven; for example, up to 60,000 km in 3 years or up to 100,000 km in 5 years. These guarantees of product quality are backed by the manufacturer’s confidence in the durability in each product. As power transfer devices like the transmission and reducer come with their own warranties that are separate from the rest of the car, durability is a very important measure of the quality and performance of a powertrain. The Hyundai Motor Group, committed to the sustainability of green cars, offers EVs and hybrids with notably consumer-friendly warranties. The power transfer components of EVs are covered by a warranty valid for up to 160,000 km in 10 years, while the power transfer components of hybrids are covered by a warranty that is valid for up to 200,000 km in 10 years.

To fulfill such high durability requirements, Hyundai Transys carries out rigorous testing of its electrified powertrains. Powertrain lifespans are identified in short periods of time by running continuous cycles of tests under harsh conditions. Inside the labs, engines and transmissions are run 24/7. In normal driving, we rarely redline the engine, but the engines and transmissions undergoing durability testing are pushed to the redline hundreds and thousands of times to provide an idea of their breaking points. The driving that occurs in these labs is so tough that an engine oil change, performed once a year under normal driving conditions, takes place about once a week.

The newest cars today are more like precision electronic devices than an assembly of mechanisms, as different parts and functions of the car are precisely controlled by controllers located on computer networks inside the car. At the Hwaseong Drivetrain R&D Center, vehicular controllers such as engine control units, transmission control units, and vehicle control units are applied to the testing of powertrains. A higher level of precision in the measurement of data is required with hybrid drive systems, as they come with additional controllers not found in ICE drive systems, including the oil pump unit and hybrid power control unit.

This means that a more extensive testing setup is required; for example, hybrid drive components being tested require separate coolant lines for the controllers involved. The integrity of the testing environment is crucial, as motor output can vary depending on high-voltage battery state of charge (SoC). Identical testing conditions must be maintained through the cycle of tests performed.

All collected data are displayed in real time on monitors outside the labs. By raising the engine RPM by stepping on the accelerator pedal, it is possible to precisely check each condition in the operation of a transmission. As hybrid transmissions are paired to an electric motor, the gleaning and analysis of data must be precise.

The Electrification Reliability Test Team recently installed a battery test system to create the SoC and voltage drop conditions exhibited in actual cars. The background to this is that while it is natural for a car to drop in SoC from driving, achieving a decreasing SoC in tests was not possible. Accordingly, the Electrification Reliability Testing Team developed an SoC and voltage reduction model from actual road data. Now, when SoC gets low in durability tests, motor power is restricted to lessen the load applied on the transmission. Thanks to the newly developed testing model, Hyundai Transys enjoyed great savings on the durability testing of its newly developed hybrid drive system.

powertrain durability is directly related to vehicle reliability, and it is the main objective of the Electrification Reliability Test Team to fully validate powertrain durability.

- Engineer Yoon Yeo-hoon

of the Electrification Reliability Testing Team -

NVH Performance Development Offers Peak Ride Comfort in Green Cars

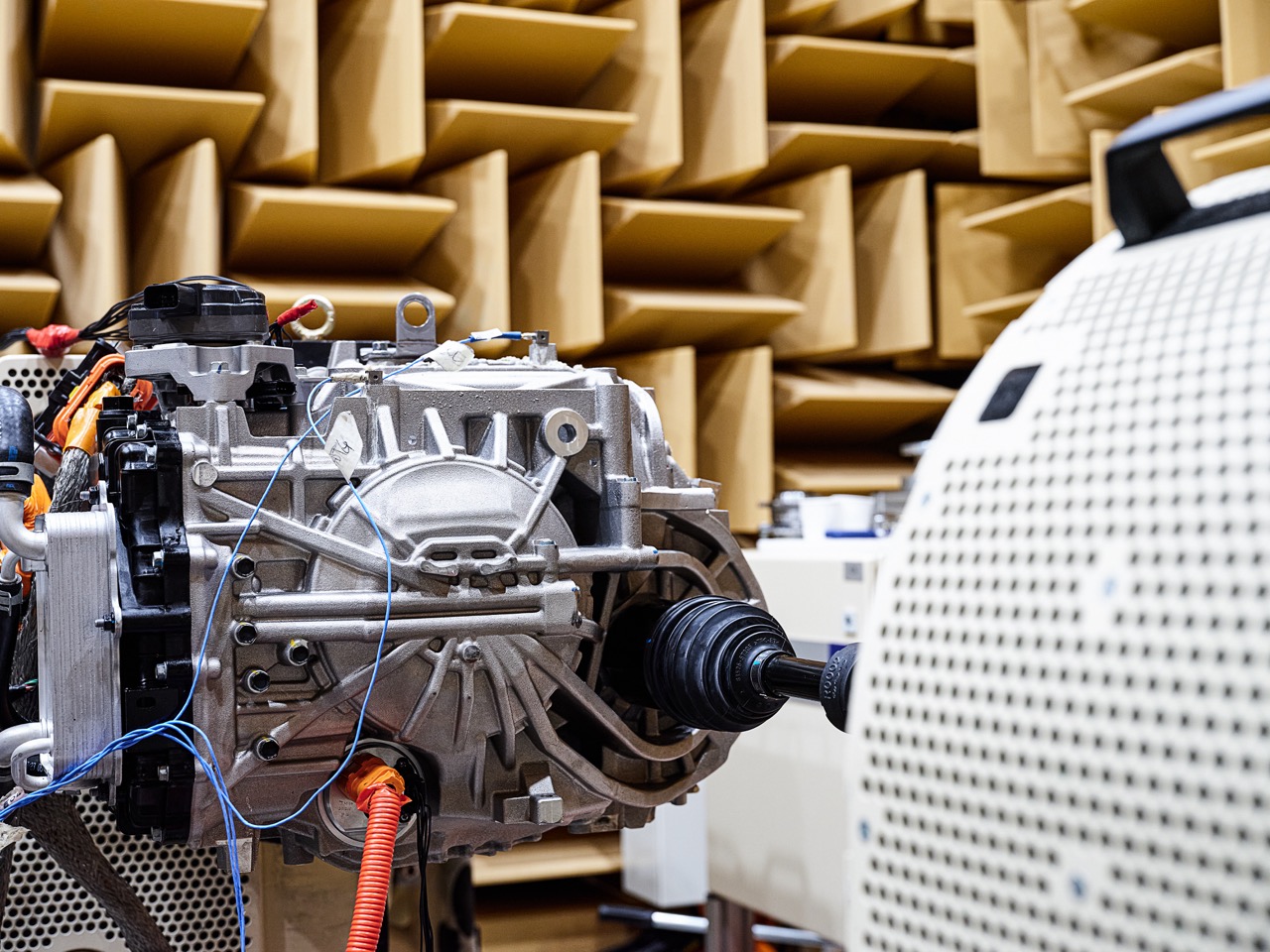

To achieve the best ride comfort, driving noise and vibration must be kept to a minimum, a process referred to as the NVH (noise, vibration, harshness) performance of a car. The NVH Development Team at Hyundai Transys is charged with analyzing and reducing the noise and vibration generated by powertrains.

Tests are performed in anechoic chambers, rooms from which outside noise and vibration are completely blocked, allowing the minutest of noises to be detected. An anechoic chamber is equipped with a high-voltage power supply for NVH performance testing of high-output motors. The setup allows the measurement of noise and vibration while a motor is running. Varying simulations, including simulations of an engine run only and of an engine-motor run, are produced to carry out comprehensive evaluations and make improvements.

As NVH performance affects the emotional appeal of a car, including how comfortable, refined, and safe the cabin feels to occupants, attention to detail is essential. Since noise and vibration suppression can come at the cost of performance, a balance must be struck between ride comfort and performance to keep consumers happy.

The NVH performance evaluation criteria applied to internal combustion engine (ICE) cars, hybrid cars, and EVs are different. While an ICE car’s transmission produces noise and vibration in the shifts between the gears, the coordinated operations of the engine and drive motor are one cause of noise and vibration in hybrid cars. The newest EVs today are more powerful than their predecessors thanks to an acceleration-supportive design that increases motor RPMs. The high speeds and high power of EVs can result in high-frequency noise. Analysis and reduction of causes of powertrain noise associated with the electrification of cars, as well as the improvement of overall NVH performance, are the core function of the NVH Performance Development Team at Hyundai Transys.

There are companies that just make really good transmissions,

and there are companies that just make really good drive systems,

but there aren’t many that can test the different powertrains that go into ICE cars, hybrid cars, and EVs on criteria fine-tuned to such variations in powertrains.

The NVH Performance Development Team is proud to give Hyundai Transys

a competitive edge in that respect

- Senior Engineer Baek Sung-hwan of the NVH Development Team -

Vehicle-in-the-loop Testing for Electrified Mobility

As a car is a vast amalgam of interacting parts, excellent standalone components may not always perform well when installed in an actual vehicle. The final step in powertrain performance and efficiency testing is in-vehicle testing.

The EV Performance Development Team tests powertrain components developed by Hyundai Transys in actual cars. At the Vehicle Test Room, the team evaluates the drivability of cars fitted with new powertrain components, looking at energy (fuel + electricity) efficiency, vehicle control to driver intent, the absence of performance issues, and other areas. It also validates Hyundai Transys-developed controllers by running them in test cars, looking at the coordinated functioning of controllers. The overarching purpose of such tests is to identify, when the accelerator pedal is depressed, how well the powertrain performs, how well energy is delivered to the powertrain, and if there are any issues.

As road testing involves certain limitations, tests are conducted in labs in which real road conditions are mimicked. With the tires constantly running on rollers, energy (fuel + electricity) efficiency is measured. All data collected from tests are shared with the teams of the Hwaseong Drivetrain R&D Center working in the areas of design, performance, and control, to form the foundation for product development.

At the Vehicle Test Room, tests were underway to set the EV benchmarks based on which EV drive systems would be developed and marketed by Hyundai Transys. The Vehicle Test Room consists of two test cells capable of testing vehicles of all sizes and drive configurations.

The giant fan in front of the test car simulates the air resistance experienced by a driving car. Synchronized with the vehicle’s wheel speed, the fan’s blow power increases as the vehicle speed picks up. Aerodynamic performance tests are among the tests this setup enables.

In the driver’s seat of the vehicle is not an actual driver, but a robot which functions to accelerate and slow down and stop the vehicle, and even perform gear shifts. Through repeated maneuvers, the vehicle’s speeds, engine/motor RPMs, torque, and other data are recorded. Such data allows the EV Performance Development Team to collaborate with the other teams at the Hwaseong Drivetrain R&D Center in developing and improving powertrain performance until diverse and exacting consumer needs are met.

Since the tests we run are the last before the cars are released on the market,

we can’t help but be obsessive about every little detail.

We test the cars, thinking of our own families using them

- Senior Engineer Han Geung-hee

of the EV Performance Development Team -

It is that sense of responsibility that leads to the convenience and safety enjoyed by all those who end up in vehicles created by the Hyundai Motor Group.

The EV Performance Development Team performs a wide range of tests for prototype validation, mass production quality improvement, and benchmarking of competitors’ cars. With advances in electrified powertrain technology taking place as we speak, the teams at the Hwaseong Drivetrain R&D Center are on a mission to develop the powertrains needed in cars that truly exceed market expectations.

The Hwaseong Drivetrain R&D Center’s innovation efforts in electrified mobility have recently borne substantial fruit. In June of this year, Hyundai Transys signed a contract to supply Ceer with KRW 3 trillion’s worth of EV drive systems. This marks the first time Hyundai Transys is supplying electrification solutions to a finished car manufacturer outside of the Hyundai Motor Group.

For Hyundai Transys, which has been growing its share of the hybrid car market through the tech-competitiveness it has acquired through years of developing and manufacturing ICE transmissions, this international deal in EV drive systems will bolster its position in the EV market.

With an extensive lineup of electrified drive systems compatible with EVs, FCEVs, HEVs, and PHEVs—all green cars—Hyundai Transys is staying a step ahead of the evolving electrified mobility market. This progress is driven by placing the customer’s voice at the forefront of green car technology development.

In the realm of green mobility technology, we are truly living in exciting times, with Hyundai Transys tirelessly working and innovating for you, the customer.

'Global' 카테고리의 다른 글

| The Power of DX: Transforming Culture with Technology (0) | 2025.09.01 |

|---|---|

| ESG: The Driving Force for Both Myself and Hyundai Transys (0) | 2025.08.25 |

| The Hyundai Transys Dongtan Seat R&D Center Leading the Evolution of Automotive Seating Technology (0) | 2024.06.24 |

| PBVs, a New Paradigm of Future Mobility (0) | 2024.06.13 |

| How Far HEVs Have Come and Their Future (0) | 2024.06.12 |